Tel:0086 17750089040

Wechat:0086 17750089040

Contact Person:MANAGER

PDF Show:PDF

DL-6CFX-F30-3QB is a new type of tea screening equipment developed by our company, It can separate fresh leaves and finished tea in one machine. It can save money and workers. It can adjust the speed of screening and wind speed. It is a necessary good helper for tea factory!

DL-6CYQT-6105 mainly used for Oolong tea processing, drum made of bamboo, the activity of withered tea was increased by shaking, It can make tea taste more fragrant, Capacity about 32 kg per batch.

This machine is suitable for the shaping and roasting process of high-grade curly tea. Tea roasted by this machine features tight and neat strips, uniform curling, bright green color, visible white fuzz, and rich aroma—fully demonstrating the characteristics of high-quality tea. The machine's heating system offers two options: electric heating and liquefied gas heating, allowing users to choose flexibly based on their actual needs.

The Matcha ball mill is designed for post-drying grinding of agricultural products (e.g., ground tea, Chinese medicinal materials) with advantages of low-temperature grinding (5-15℃) to retain raw material color and aroma, fine fineness (500-1000 meshes), PLC-controlled easy operation, and durable structure.

The Matcha ball mill is designed for post-drying grinding of agricultural products (e.g., ground tea, Chinese medicinal materials) with advantages of low-temperature grinding (5-15℃) to retain raw material color and aroma, fine fineness (500-1000 meshes), PLC-controlled easy operation, and durable structure.

Single Semi-automatic Tea Pressing Machine, working with a small granular filling machine, enables quantitative filling and efficient pressing. Powered by 220V and 4.0KW, it produces 500 pieces per hour, supporting round tea cakes (20.0-35.0mm) and dragon ball-shaped teas (20.0-27.0mm). User-friendly and safe, it’s ideal for processing Pu-erh, white, and dark compressed teas.

Discover the LS3CX - 750 High Efficiency Wheel Trimmer, your ultimate solution for pruning in gardens, along roads, and in tea gardens. This trimmer comes with an adjustable height function, enabling you to adapt to different plant heights. Its high - performance cutting system ensures efficient and clean cuts on grass, shrubs, and tea branches. With a user - friendly wheel - based design, it offers easy maneuverability, making pruning tasks a breeze. Ideal for both professional landscapers and gardening enthusiasts.

4C-60L is a handheld automatic tea plucking machine designed for tea gardens. Equipped with a 2-stroke gasoline engine and a 600mm reciprocating cutter head, it efficiently harvests tea leaves with precision. Weighing only 10-14.3kg and featuring a backpack design, it ensures flexible and lightweight operation for prolonged use.

The 0.7L fuel tank supports hours of continuous work, while the centrifugal friction clutch transmission system delivers stable power and easy maintenance. Its comb-type cutting technology separates buds and leaves accurately, minimizing damage, and the negative-pressure suction tube directly collects fresh leaves into a waist-mounted bag, integrating "picking-collection" into one process

DL-6CST-90 mainly used for Green/Oolong/Yellow tea processing, inside drum diameter 90cm, length 124cm, use gas heating, speed and temperature adjustable. Capacity about 100 kg per hour.

| DESCRIPTION |

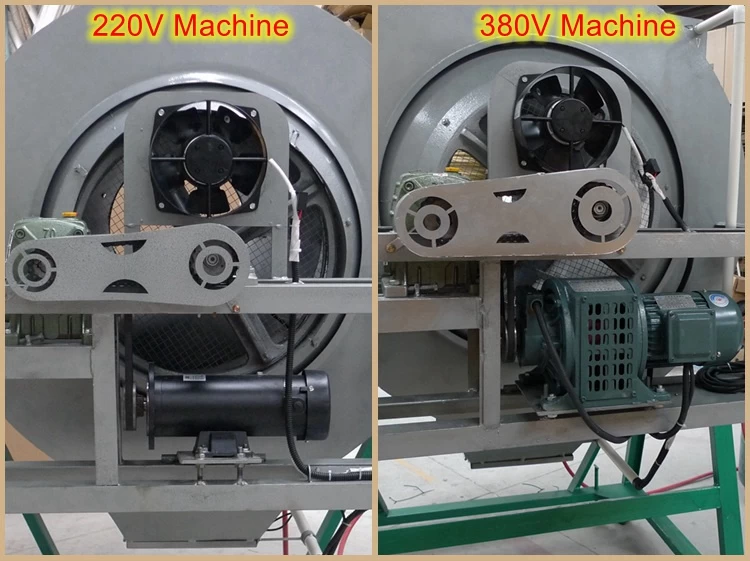

The diameter of this Cylinder Green Tea Leaf Roasting Machine is 90cm, and the length of the inner straight section is 1240mm. Using 220V/380 voltage, it can process 10 kg of fresh leaves per batch.

Excellent heat insulation, heat preservation and energy saving, using calcium silicate board, increasing the heat preservation effect and meeting the food hygiene requirements.

Increased insulation of the front plate of the drum, intelligent temperature control system, easy to operate and precise control, hand and self-integration control, double guarantee.

Large feed inlet, easy to feed, and faster discharge. The dryness of the products coming out before and after is more uniform, the taper size is longer, and the material is not dropped.

The inner cylinder adopts a steel plate with a thickness of 2.5mm to prevent the deformation of the cylinder at high temperature. The work can store energy, less heat loss, smaller temperature change and more energy saving.

| EXPLODED VIEW |

| ① | Control Pannel | ⑧ | Heat Sink |

| ② | Thermometer | ⑨ | Handle |

| ③ | Outer Barrel | ⑩ | Gearbox |

| ④ | Inner Barrel | ⑪ | Balance bolt |

| ⑤ | Support Wheel | ⑫ | Reduction cylinder |

| ⑥ | Ignition Switch | ⑬ | Combustion Zone |

| ⑦ | Bottom Wheel | ⑭ | Support Frame |

| ADVANTAGE |

1. Machine with casters, easy to move.

2. With support frame function to prevent damage to nylon wheels.

3. Adjustable drum roller inclination, machine can also be used in uneven places.

4. T-shaped combustion fire platoon covering the tea fixation barrel, burning area up to 100%.

5. Pneumatic shock absorber design, the machine automatically falls back, and the falling speed is stable.

| APPLICATION |

Tea Leaf Roasting Machine is suitable for processing green / oolong / herbal tea, the following is the working time required for the above tea production.

| Type Of Tea | Working Time |

| Green Tea | 4-8 Minutes |

| Oolong Tea | 4-8 Minutes |

| Herbal Tea | 4-8 Minutes |

The above data is for reference only, and the specific processing time shall be determined according to the actual situation.

| SPECIFICATION |

Cylinder Green Tea Leaf Roasting Machine specification list:

| Model | DL-6CST-90 | |

| Dimensions | 1230×2100×1840 mm | |

| Voltage | 380/50 V/Hz | |

| Drum inner diameter | 900 mm | |

| Drum inner length | 1240 mm | |

| Drive motor | Power | 0.75 KW |

| Speed | 1390 rpm | |

| Voltage | 380 V | |

| Exhaust fan | Power | 85 W |

| Speed | 2200 rpm | |

| Voltage | 220 V | |

| Drum speed | 5-37 rpm | |

| Heating type | Liquid gas | |

| Capacity per time | 10 kg/time | |

| Efficiency | 100 kg/h | |

Specification of all of Tea Roasting Processing Machine.

| Model | 6CST-50 | 6CST-70 | 6CST-90 | 6CST-100 |

| Drum Diameter | 50 cm | 70 cm | 90 cm | 100 cm |

| Drum Length | 60 cm | 100 cm | 124 cm | 125 cm |

| Capacity | 25 kg/h | 50 kg/h | 100 kg/h | 150 kg/h |

If you have special need, it can be customized according to the needs of customers.

| DETAILS |

The speed of the tea fixation machine can be adjusted, according to the tea of different producing areas, different speed can be adjusted

Pneumatic shock absorber design, the machine automatically falls back, and the falling speed is stable.

Optimized deceleration system, the machine speed is stable, while ensuring that the torque is large enough and running smoothly.

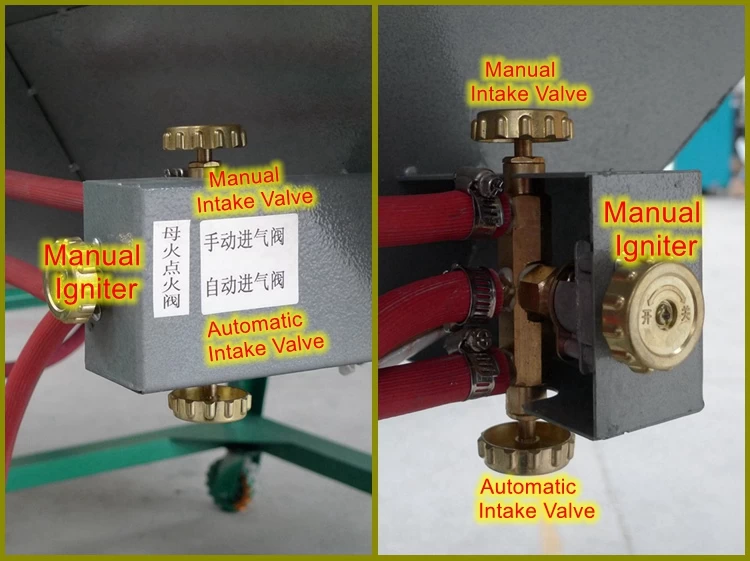

There are three valves at the bottom, which can be manually ignited in case of power failure, so tea leaves are not wasted.

Automatic solenoid valve design, heating automatically starts and stops, the solenoid valve automatically closes when the temperature reaches the set temperature, and the machine stops heating. When the temperature is lower than the set temperature, the solenoid valve opens and the machine reheats, which can save fuel.

| PHOTOS |

.JPG.webp)

.JPG.webp)

.jpg.webp)

| CONTACT |

If you are interested in this product, please contact us to get the price.

↑ ↑ Click the icon to get the latest price directly ↑ ↑

↓ ↓ You can also leave your contact information at the bottom. We usually contact you in about 10 minutes ↓ ↓

Tel:0086 17750089040

Wechat:0086 17750089040

Contact Person:MANAGER

PDF Show:PDF

Highly customized tea processing machine to meet your special needs, strictly product quality control is our requirement .