Tel:0086 17750089040

Wechat:0086 17750089040

Contact Person:MANAGER

PDF Show:PDF

DL-6CYMJ-32 Electric Black Gold Stone Matcha Grinder: grinds to ≤15μm, capacity ~50g/h, 0.55KW. Ideal for premium, small-batch fine matcha.

DL-6CSTL-CM50 for processing Green/Oolong tea, use wood, coal or pellet fuel heating, drum diameter 50cm, length 260cm, speed and temperature adjustable. Capacitu about 50 kg per hour.

DL-6CSTP-D110 for processing Green/Oolong tea, use wood, coal or pellet fuel heating, drum diameter 110cm, length 100cm, speed and temperature adjustable. Capacitu about 100 kg per hour.

DL-6CSTL-Q80 for processing Green/Oolong tea, use wood, coal or pellet fuel heating, drum diameter 80cm, length 400cm, speed and temperature adjustable. Capacitu about 150 kg per hour.

DL-6CFX-435 can used for all kind tea, through the volume of air blowing, different weight tea are blown to different positions and screened out through the corresponding outlet, 5 different sizes of tea can be selected.

DL-6CFX-F30-3QB is a new type of tea screening equipment developed by our company, It can separate fresh leaves and finished tea in one machine. It can save money and workers. It can adjust the speed of screening and wind speed. It is a necessary good helper for tea factory!

DL-6CYQT-6105 mainly used for Oolong tea processing, drum made of bamboo, the activity of withered tea was increased by shaking, It can make tea taste more fragrant, Capacity about 32 kg per batch.

This machine is suitable for the shaping and roasting process of high-grade curly tea. Tea roasted by this machine features tight and neat strips, uniform curling, bright green color, visible white fuzz, and rich aroma—fully demonstrating the characteristics of high-quality tea. The machine's heating system offers two options: electric heating and liquefied gas heating, allowing users to choose flexibly based on their actual needs.

DL-6CST-100 mainly used for Green/Oolong/Yellow tea processing, inside drum diameter 90cm, length 125cm, use gas heating, speed and temperature adjustable. Capacity about 150 kg per hour.

| DESCRIPTION |

The diameter of this Tea Roaster Machine is 100cm, and the length of the inner straight section is 1250mm. Using 220V/380 voltage, it can process 15 kg of fresh leaves per batch.

Integrated microcomputer control system, the fixation time can be intelligently controlled, adopt dual temperature control design, ensure the precise control of temperature and ensure the quality of tea, when tea fixation, the speed of the machine can be adjusted, according to the tea of different producing areas, different speed can be adjusted.

Using 2.5mm ultra-thick steel plate, the temperature change is small and good heat preservation, the tea leaf will not be damaged, ( other factory only use 1.6mm steel plate ), preserve the design of the combustion head of the constant burning flame, reserve the constant burning flame after the ignition is successful, re-ignite from the constant burning flame, reduce the pressure of the ignition needle and the ignition coil, and improve the service life.

| EXPLODED VIEW |

| ① | Control Pannel | ⑧ | Heat Sink |

| ② | Thermometer | ⑨ | Handle |

| ③ | Outer Barrel | ⑩ | Gearbox |

| ④ | Inner Barrel | ⑪ | Balance bolt |

| ⑤ | Support Wheel | ⑫ | Reduction cylinder |

| ⑥ | Ignition Switch | ⑬ | Combustion Zone |

| ⑦ | Bottom Wheel | ⑭ | Support Frame |

| ADVANTAGE |

1. Alarm device, automatic alarm can be given at the end of the set time.

2. There is a handle on the drum, which can be manually roasting in case of a sudden power failure, so that the tea is not wasted.

3. Optimized deceleration system, the machine speed is stable, while ensuring that the torque is large enough and running smoothly.

4. The inner barrel uses a new type of environmentally friendly fireproof insulation material, thickness up to 20mm, greatly reduces heat loss and saves energy by 30%.

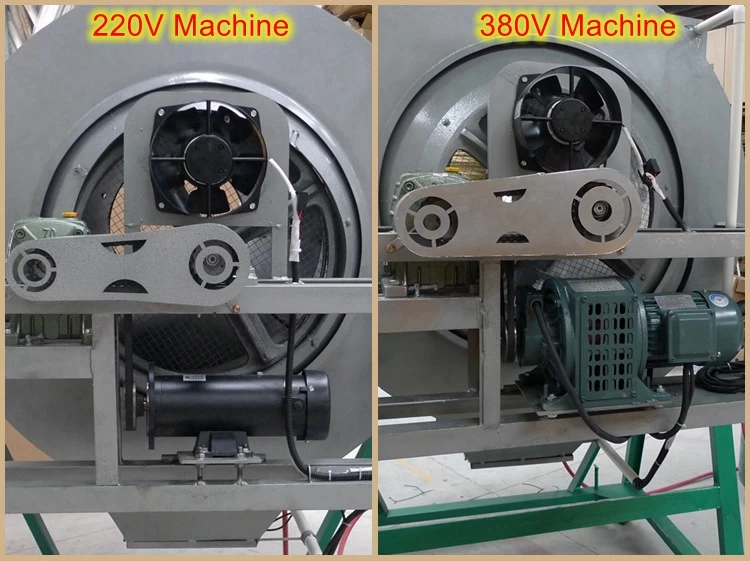

5. An exhaust fan is added to the rear, which can be turned on and off manually, which can quickly blow away the hot and humid air inside the machine to prevent the tea from being stuffy and affecting the taste.

| APPLICATION |

Green Tea Roaster is suitable for processing green / oolong / herbal tea, the following is the working time required for the above tea production.

| Type Of Tea | Working Time |

| Green Tea | 4-8 Minutes |

| Oolong Tea | 4-8 Minutes |

| Herbal Tea | 4-8 Minutes |

The above data is for reference only, and the specific processing time shall be determined according to the actual situation.

| SPECIFICATION |

Tea Roaster Machine specification list:

| Model | DL-6CST-100 | |

| Dimensions | 1330×2400×2010 mm | |

| Voltage | 380/50 V/Hz | |

| Drum inner diameter | 1000 mm | |

| Drum inner length | 1250 mm | |

| Drive motor | Power | 0.75 KW |

| Speed | 1400 rpm | |

| Voltage | 380 V | |

| Exhaust fan | Power | 85 W |

| Speed | 2200 rpm | |

| Voltage | 220 V | |

| Drum speed | 5-37 rpm | |

| Heating type | Liquid gas | |

| Capacity per time | 15 kg/time | |

| Efficiency | 150 kg/h | |

Specification of all of Tea Steam Roaster.

| Model | 6CST-50 | 6CST-70 | 6CST-90 | 6CST-100 |

| Drum Diameter | 50 cm | 70 cm | 90 cm | 100 cm |

| Drum Length | 60 cm | 100 cm | 124 cm | 125 cm |

| Capacity | 25 kg/h | 50 kg/h | 100 kg/h | 150 kg/h |

If you have special need, it can be customized according to the needs of customers.

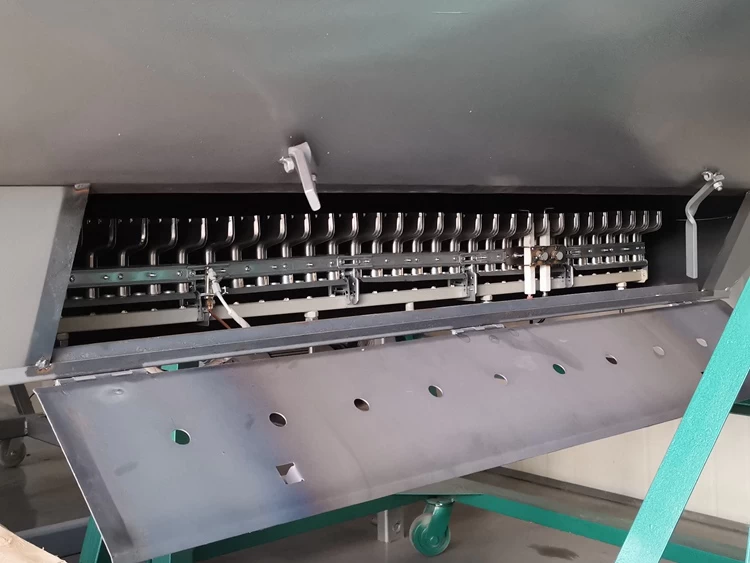

| DETAILS |

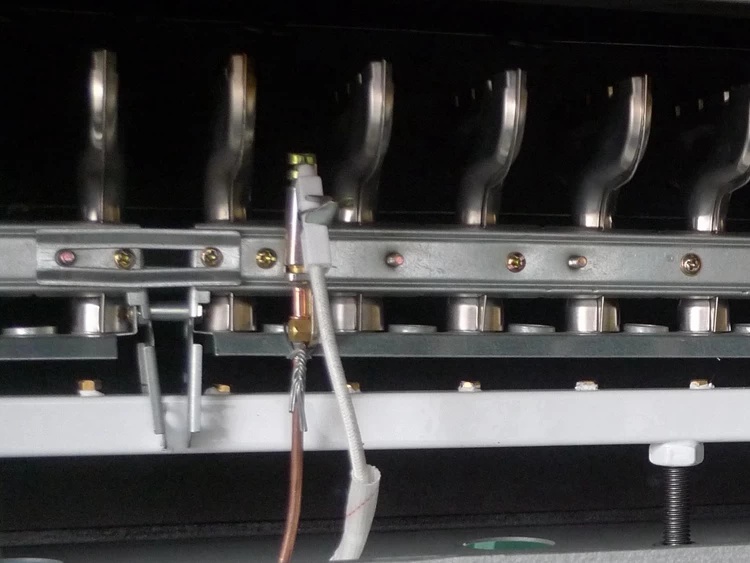

T-shaped combustion fire platoon covering the tea fixation barrel, burning area up to 100%.

The inner barrel uses a new type of environmentally friendly fireproof insulation material, thickness up to 20mm, greatly reduces heat loss and saves energy by 30%.

Optimized deceleration system, the machine speed is stable, while ensuring that the torque is large enough and running smoothly.

Preserve the design of the combustion head of the constant burning flame, reserve the constant burning flame after the ignition is successful, re-ignite from the constant burning flame, reduce the pressure of the ignition needle and the ignition coil, and improve the service life.

Using 2.5mm ultra-thick steel plate, the temperature change is small and good heat preservation, the tea leaf will not be damaged, ( other factory only use 1.6mm steel plate )

| PHOTOS |

.JPG.webp)

.JPG.webp)

.jpg.webp)

| CONTACT |

If you are interested in this product, please contact us to get the price.

↑ ↑ Click the icon to get the latest price directly ↑ ↑

↓ ↓ You can also leave your contact information at the bottom. We usually contact you in about 10 minutes ↓ ↓

Tel:0086 17750089040

Wechat:0086 17750089040

Contact Person:MANAGER

PDF Show:PDF