Tel:0086 17750089040

Wechat:0086 17750089040

Contact Person:MANAGER

PDF Show:PDF

DL-6CFX-F30-3QB is a new type of tea screening equipment developed by our company, It can separate fresh leaves and finished tea in one machine. It can save money and workers. It can adjust the speed of screening and wind speed. It is a necessary good helper for tea factory!

DL-6CYQT-6105 mainly used for Oolong tea processing, drum made of bamboo, the activity of withered tea was increased by shaking, It can make tea taste more fragrant, Capacity about 32 kg per batch.

This machine is suitable for the shaping and roasting process of high-grade curly tea. Tea roasted by this machine features tight and neat strips, uniform curling, bright green color, visible white fuzz, and rich aroma—fully demonstrating the characteristics of high-quality tea. The machine's heating system offers two options: electric heating and liquefied gas heating, allowing users to choose flexibly based on their actual needs.

The Matcha ball mill is designed for post-drying grinding of agricultural products (e.g., ground tea, Chinese medicinal materials) with advantages of low-temperature grinding (5-15℃) to retain raw material color and aroma, fine fineness (500-1000 meshes), PLC-controlled easy operation, and durable structure.

The Matcha ball mill is designed for post-drying grinding of agricultural products (e.g., ground tea, Chinese medicinal materials) with advantages of low-temperature grinding (5-15℃) to retain raw material color and aroma, fine fineness (500-1000 meshes), PLC-controlled easy operation, and durable structure.

Single Semi-automatic Tea Pressing Machine, working with a small granular filling machine, enables quantitative filling and efficient pressing. Powered by 220V and 4.0KW, it produces 500 pieces per hour, supporting round tea cakes (20.0-35.0mm) and dragon ball-shaped teas (20.0-27.0mm). User-friendly and safe, it’s ideal for processing Pu-erh, white, and dark compressed teas.

Discover the LS3CX - 750 High Efficiency Wheel Trimmer, your ultimate solution for pruning in gardens, along roads, and in tea gardens. This trimmer comes with an adjustable height function, enabling you to adapt to different plant heights. Its high - performance cutting system ensures efficient and clean cuts on grass, shrubs, and tea branches. With a user - friendly wheel - based design, it offers easy maneuverability, making pruning tasks a breeze. Ideal for both professional landscapers and gardening enthusiasts.

4C-60L is a handheld automatic tea plucking machine designed for tea gardens. Equipped with a 2-stroke gasoline engine and a 600mm reciprocating cutter head, it efficiently harvests tea leaves with precision. Weighing only 10-14.3kg and featuring a backpack design, it ensures flexible and lightweight operation for prolonged use.

The 0.7L fuel tank supports hours of continuous work, while the centrifugal friction clutch transmission system delivers stable power and easy maintenance. Its comb-type cutting technology separates buds and leaves accurately, minimizing damage, and the negative-pressure suction tube directly collects fresh leaves into a waist-mounted bag, integrating "picking-collection" into one process

100kg fresh leaves process 25kg finished oolong tea in 12 hours, This page recommends you a full set of green tea production equipment and use methods.

For the tea equipment recommended on this page, the water content of fresh tea leaf is 75% and that of dry tea is 5%.

According to our local tea production data, 4kg wet tea leaf produces 1kg dry tea.

| Mositure Content (%) | Total Weight (kg) | |

| Orginal | ≈ 75% | ≈ 100kg |

| After Withering | ≈ 73% | ≈ 95kg |

| After Shaking / Tossing | ≈ 60% | ≈ 65kg |

| After Fixing | ≈ 45% | ≈ 45kg |

| After Rolling | ≈ 45% | ≤ 45kg |

| After Drying | ≤ 5% | ≤ 26kg |

The above data are from our local tea production data, and there may be deviations in tea production in different regions.

| 1. Withering |

Oolong tea withering step is sunning withering, put the tea leaves under the sun about 30-60 minutes, the best time to choose is 4:00pm - 5:00pm, flip the tea leaf every 10 minutes, make the water content drop to about 78%, the aroma of tea began to show.

We recommend use 2 sets DL-TQJ-20 tea withering rack, capacity 50kg per batch, for 100kg tea leaf need 2 sets, put tea leaves on the bamboo pallets and put under the sun.

With 20pcs Bamboo Pallets Tea Natural Wither Rack DL-TQJ-20

| Recommended Working Data | |

| Temp | Room Temperature |

| Time | 30-60 minutes |

| Capacity | 2.5 kg per tray |

The mositure content after withering step will drop to 73%, total weight of tea leaf about 95kg.

| 2. Shaking / Tossing |

Shaking and withering are both parts of the fermentation. During the withering process of oolong tea, because the leaves are calmly placed, a lot of water will only evaporate from the leaves, and the water in the leaf stalks is not lost, which will lead to the bitterness of the tea leaves is very strong, which seriously affects the quality of oolong tea. It is necessary to shake. Through the shaking process, the activity of the leaves is enhanced. The water in the leaf stalks continues to be transported to the leaves, allowing the leaves to re-evaporate the water, Distribute the grassy smell of tea leaves, so that the taste of the finished oolong tea will not very bitter, greatly improving the quality of oolong tea.

We recommend use 1 set DL-6CYQT-60 oolong tea shaking drum, capacity 32kg per batch, for 95kg tea leaf need 1 set.

After shaking, oolong tea needs to be placed on the withering racks in the first step (each rest time should be put tea on the bamboo pallets).

Oolong tea should be green with red edges after shaking, which means that the inside of the leaf is still green, but the edge of the leaf is red.

Oolong Tea Processing Shaking Bamboo Drum Machine DL-6CYQT-6015

| Recommended Working Data | |

| Temperature | ≈20℃ |

| Ambient Humidity | ≈50% |

| First Shaking Rest Time | 3-4 minutes |

| Second Shaking Time | 1.5-2 Hours |

| Second Shaking Rest Time | 5-10 minutes |

| Third Shaking Time | 2-2.5 Hours |

| Third Shaking Rest Time | 20-25 Minutes |

| Shaking Speed | 6-12 Hours |

| Capacity | 32 kg/batch |

The mositure content after shaking step will drop to 60%, total weight of tea leaf about 65kg.

| 3. Fixing |

The step of fixation is mainly used for the production of various unfermented or semi-fermented teas. The activity of the enzyme in the fresh leaves is reduced by high temperature, the tea polyphenols in the fresh leaves are stopped for oxidative fermentation, and the odor of the grass is removed, the aroma of the tea leaves is excited, and the moisture in the fresh leaves is evaporated. The fresh leaves become softer, which is conducive to the subsequent rolling process, and the tea leaves are not easily damaged.

We recommend use 1 set DL-6CST-50B tea fixation machine, capacity 25kg per hour, for 65kg tea leaf need 1 set, working time about 2.5 hours.

50cm Diameter Gas Heating Green/Oolong/Yellow Tea Fixation Machine DL-6CST-50

| Recommended Working Data | |

| Temperature | 250℃ - 320℃ |

| Time | 5-7 Minutes |

| Rotate Speed | 30 rpm |

| Capacity | 2.5 kg per batch |

The mositure content after withering step will drop to 45%, total weight of tea leaf about 45kg.

| 4. Rolling |

Different tea leaves have different rolling time and different functions.

For oolong tea: Oolong tea is the semi-fermented tea. Through the process of withering and shaking, some tea leaves have already begun to ferment. But after fixation, the tea leaves stopped fermenting again, so the most important function for oolong tea is shaping like green tea. When it is twisted into the desired shape, rolling operation could be stopped and proceed to the next processing.

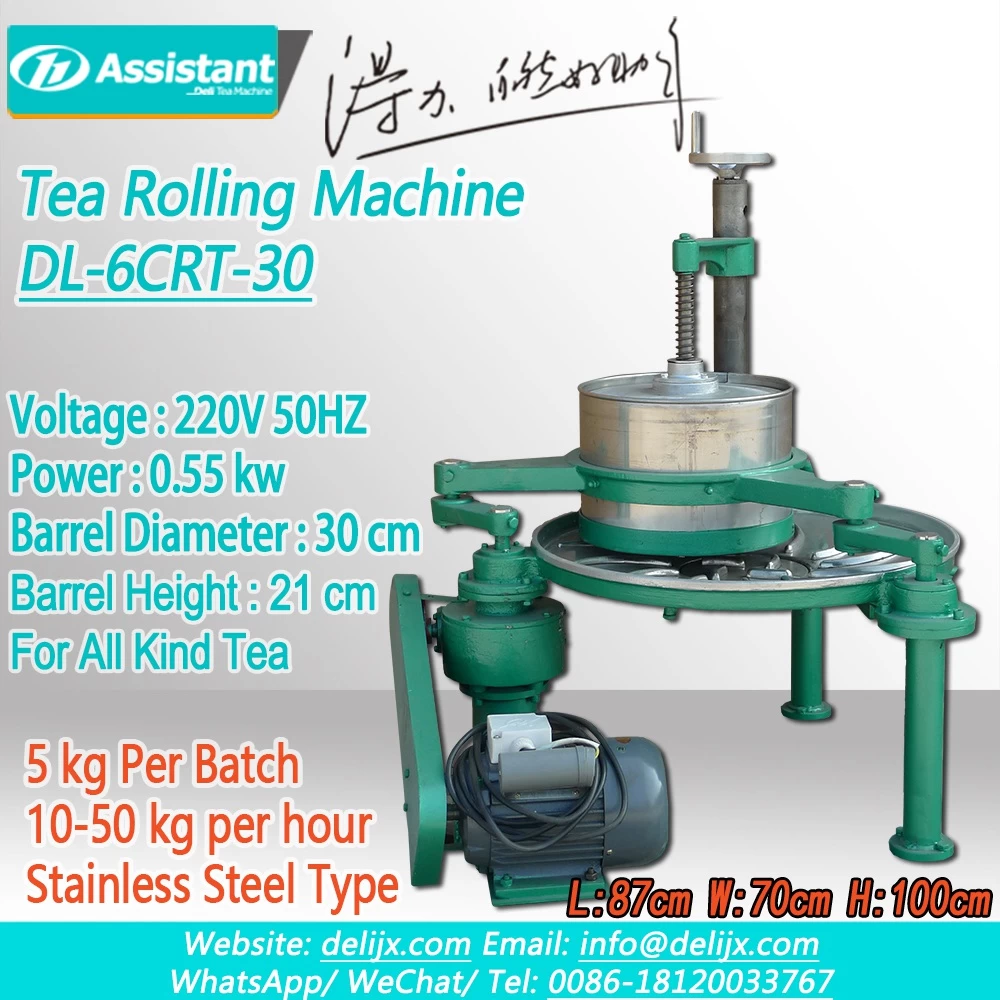

We recommend use 1 set DL-6CRT-30 Tea Rolling Machine, capacity 5kg per batch, for 45kg tea leaf need 1 set, working time about 1-2 hours.

30cm Drum Smaller Cheaper SS Type Tea Leaf Rolling Machine DL-6CRT-30

| Recommended Working Data | |

| Rotate Speed | 42 rpm |

| Time | About 10 Minutes |

| Capacity | 5 kg per batch |

The mositure content after rolling step will not change, mositure content still 45%, total weight of tea leaf about 45kg.

| 5. Drying |

The drying of oolong tea is usually to evaporate the moisture in the tea leaves so that the tea leaves are tightened and shaped, more compact, and the green grass flavor is exuded to enhance the aroma of oolong tea.

We recommend use 1 set DL-6HZ-5 Tea Drying Machine, capacity 15-20kg per batch, for 45kg tea leaf need 1 set, working time about 2 hours.

14 Layers 70cm Tray Smaller Rotating Tea Drying Machine DL-6CHZ-5QB

| Recommended Working Data | |

| Temperature | 85℃ - 95℃ |

| Rotate Speed | 6 rpm |

| Time | 40-60 Minutes |

| Capacity | 15-20 kg/batch |

The mositure content after rolling step will drop to less than 5%, total weight of tea leaf about 25kg.

| 6. Sorting |

In the process of making tea, due to the different size, shape and age of the collected tea, the quality of the tea produced is also different. And the tea may be broken during the production process, we need to classify different grades and different sizes. The teas are selected, and different grades of tea are sold at different prices, thus maximizing the profit of tea production.

Small Type Tea Winnower Sorter Screener Machine DL-6CFX-435QB

| 7. Packing |

For different regions and customers, we can't know everyone's different needs for packaging. For different packaging, you can visit the following links to choose your favorite packaging.

| Get Quotation |

The following is the summary model and required quantity of equipment recommended on this page:

| Name | Model | Quantity |

| Tea Withering Rack | DL-TQJ-20 | 2 |

| Tea Shaking Machine | DL-6CYQT-6015 | 1 |

| Tea Fixing Machine | DL-6CST-50B | 1 |

| Tea Rolling Machine | DL-CRT-30 | 1 |

| Tea Drying Machine | DL-6CHZ-5 | 1 |

| Tea Sorting Machine | DL-6CFX-435QB | 1 |

Contact us in the following ways to obtain the quotation of the equipment recommended on this page.

↑ ↑ Click the icon to get the quotation directly ↑ ↑

Tel:0086 17750089040

Wechat:0086 17750089040

Contact Person:MANAGER

PDF Show:PDF

Highly customized tea processing machine to meet your special needs, strictly product quality control is our requirement .