Tel:0086 17750089040

Wechat:0086 17750089040

Contact Person:MANAGER

PDF Show:PDF

DL-6CYMJ-32 Electric Black Gold Stone Matcha Grinder: grinds to ≤15μm, capacity ~50g/h, 0.55KW. Ideal for premium, small-batch fine matcha.

DL-6CSTL-CM50 for processing Green/Oolong tea, use wood, coal or pellet fuel heating, drum diameter 50cm, length 260cm, speed and temperature adjustable. Capacitu about 50 kg per hour.

DL-6CSTP-D110 for processing Green/Oolong tea, use wood, coal or pellet fuel heating, drum diameter 110cm, length 100cm, speed and temperature adjustable. Capacitu about 100 kg per hour.

DL-6CSTL-Q80 for processing Green/Oolong tea, use wood, coal or pellet fuel heating, drum diameter 80cm, length 400cm, speed and temperature adjustable. Capacitu about 150 kg per hour.

DL-6CFX-435 can used for all kind tea, through the volume of air blowing, different weight tea are blown to different positions and screened out through the corresponding outlet, 5 different sizes of tea can be selected.

DL-6CFX-F30-3QB is a new type of tea screening equipment developed by our company, It can separate fresh leaves and finished tea in one machine. It can save money and workers. It can adjust the speed of screening and wind speed. It is a necessary good helper for tea factory!

DL-6CYQT-6105 mainly used for Oolong tea processing, drum made of bamboo, the activity of withered tea was increased by shaking, It can make tea taste more fragrant, Capacity about 32 kg per batch.

This machine is suitable for the shaping and roasting process of high-grade curly tea. Tea roasted by this machine features tight and neat strips, uniform curling, bright green color, visible white fuzz, and rich aroma—fully demonstrating the characteristics of high-quality tea. The machine's heating system offers two options: electric heating and liquefied gas heating, allowing users to choose flexibly based on their actual needs.

DL-6CRT-65 can process almost all kind tea, the part contacted with tea is made of stainless steel, drum diameter 65cm, height 48cm, capacity about 60 kg per batch.

| DESCRIPTION |

Tea rolling machine can use for most of tea such as black tea, green tea, and oolong tea, for green tea ( non-fermented ) is mainly used for shaping the strip type, for black tea ( fermented tea ) is mainly used to destroy the cells of fresh tea leaves, so that the juice in tea can flow out and facilitate subsequent fermentation.

Through the external force of the tea roller machine, the tea leaf's juice overflows, the tea cells are damaged, fresh tea leaf is twisted and curled into a strip shape, the juice in the fresh tea leaves is squeezed out. When brewing, the taste is stronger, the color of the tea soup is brighter and the quality of the tea is better.

| ADVANTAGE |

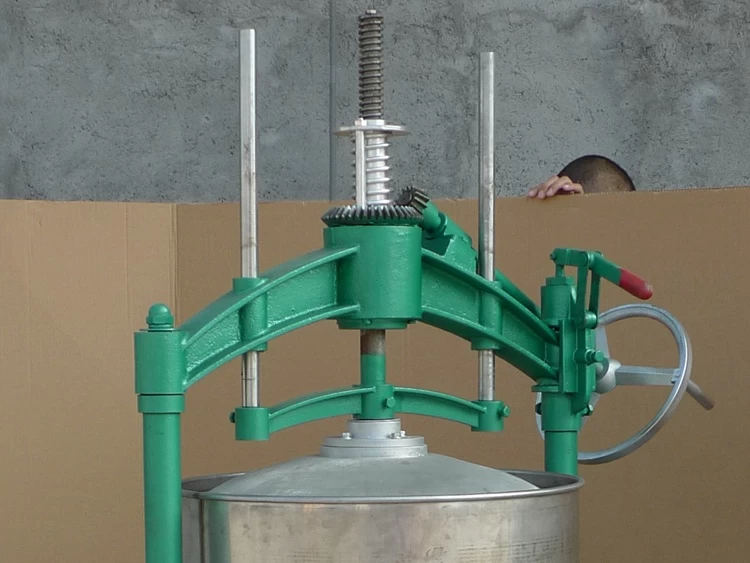

1. Turbine worm gearbox design, deceleration is stable and durable.

2. The bottom discharge handle design, gently push the handle, the tea can fall easily.

3. The heightened design of the rolling barrel can prevent the tea leaves from falling.

4. The supporting part of the machine is made of cast iron, which is strong and durable.

5. The arc of the rolling bar has been improved for decades, and the optimal design has been obtained. The efficiency of tea leaves been the strip-type is increased by 30%.

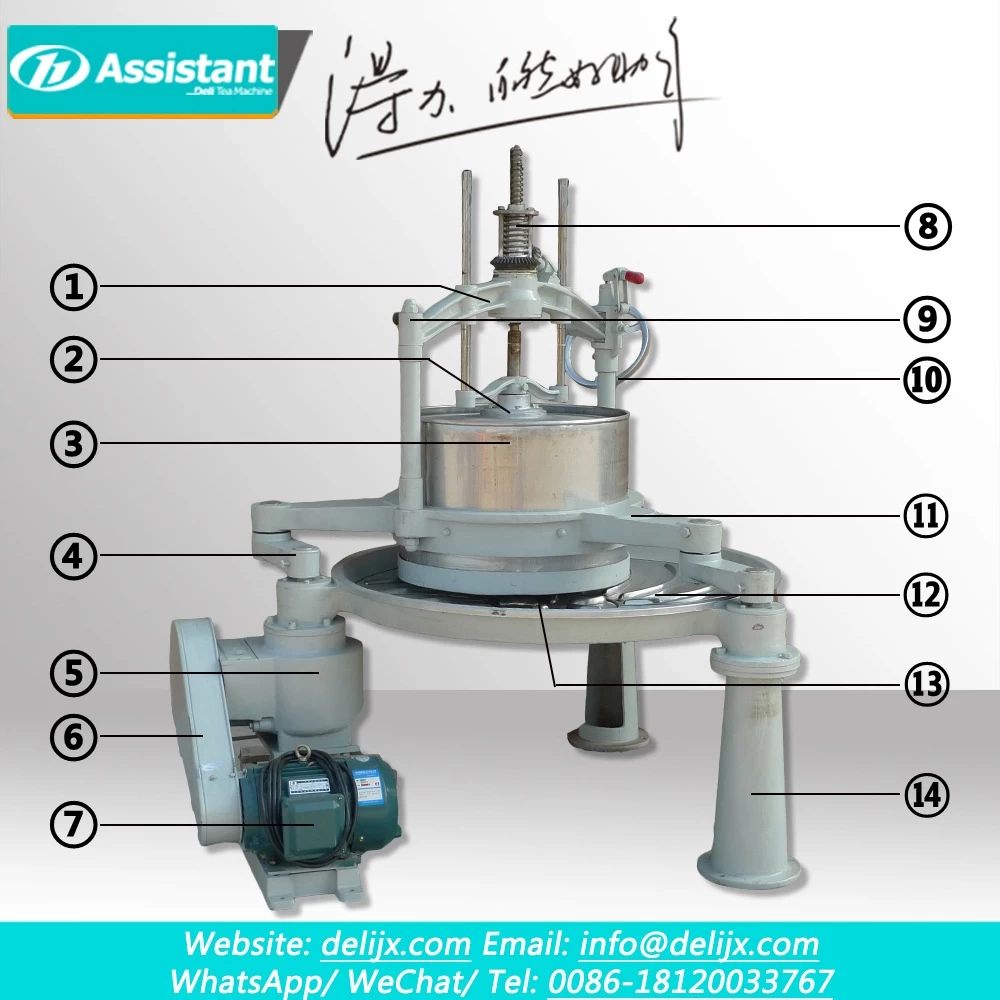

| EXPLODED VIEW |

| ① | Transverse arm | ⑧ | Press spring |

| ② | Barrel cover | ⑨ | Support column |

| ③ | Stainless steel Drum | ⑩ | Handwheel |

| ④ | Crank | ⑪ | Support frame |

| ⑤ | Transmission case | ⑫ | Rolling disc |

| ⑥ | Transmission belt | ⑬ | Tea outlet |

| ⑦ | Drive motor | ⑭ | Support leg |

| APPLICATION |

Tea Rolling Table Machine is suitable for processing black / green / oolong / white / dark / herbal tea, the following is the working time required for the above tea production.

| Type Of Tea | Working Time |

| Black Tea | 30-90 minutes |

| Green Tea | 4-6 minutes |

| Oolong Tea | 4-6 minutes |

| Herbal Tea | 4-6 minutes |

The above data is for reference only, and the specific processing time shall be determined according to the actual situation.

| SPECIFICATION |

Tea Rolling Table Machine specification list:

| Model | DL-6CRT-65 | |

| Dimension | 1490*1390*1620 mm | |

| Input voltage | 380V / 50Hz | |

| Tea disc diameter | 1210 mm | |

| Barrel diameter | 650 mm | |

| Barrel height | 480 mm | |

| Matching motor | Power | 4 kW |

| Speed | 1400 RPM | |

| Rated voltage | 380 V | |

| Barrel speed | 44 RPM | |

| Weight | 495 Kg | |

| Max capacity per batch | 60 kg/batch | |

| Capacity for green tea | 60-600 kg/h | |

| Capacity for black tea | 60-120 kg/h | |

Specification of all of Tea Rolling Table Machine.

| Model | Barrel Diameter | Barrel Height | Capacity |

| 6CRT-25 | 25 cm | 18 cm | 3 kg/batch |

| 6CRT-30 | 30 cm | 21 cm | 5 kg/batch |

| 6CRT-35 | 35 cm | 26 cm | 8 kg/batch |

| 6CRT-40 | 40 cm | 25 cm | 11 kg/batch |

| 6CRT-45 | 45 cm | 28 cm | 15 kg/batch |

| 6CRT-50 | 50 cm | 28 cm | 20 kg/batch |

| 6CRT-55 | 55 cm | 40 cm | 35 kg/batch |

| 6CRT-65 | 65 cm | 48 cm | 60 kg/batch |

If you have special need, it can be customized according to the needs of customers.

| DETAILS |

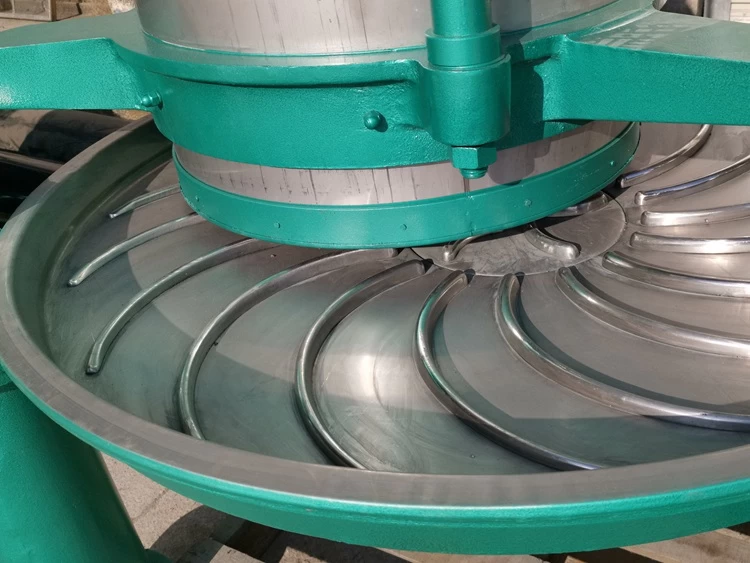

The distance between the rolling barrel and the rolling disc of each machine is different to ensure that each machine can make the best quality tea.

The supporting part of the machine is made of cast iron, which is strong and durable.

The double arms adopt a double-arm open cover structure, which has a strong bearing capacity and stable operation.

The unique design of rolling disc and rolling bar inclination angle, the speed is increased by 30% compared with other companies.

| PHOTOS |

.JPG.webp)

.jpg.webp)

.jpg.webp)

| CONTACT |

If you are interested in this product, please contact us to get the price.

↑ ↑ Click the icon to get the latest price directly ↑ ↑

↓ ↓ You can also leave your contact information at the bottom. We usually contact you in about 10 minutes ↓ ↓

Tel:0086 17750089040

Wechat:0086 17750089040

Contact Person:MANAGER

PDF Show:PDF