The DL-6CYL-800 automatic tea cake pressing machine is applicable for pressing ball type tea, round tea cakes and square tea cakes. Its production capacity is 800-1000 pieces per hour. The sizes of tea cakes that this machine can produce are as follows: square tea cakes (25-40 mm), round tea cakes (25-45 mm), and ball type tea (27-35 mm).

Oolong Tea Rolling Machine specializes in tea rolling and shaping. With precise pressure control, it releases tea juice, enhances aroma, ensures stable quality, and suits green tea, oolong tea, etc.—a top choice for tea enterprises.

DL-CRQ-20Z CTC black tea HRS Gyrovane rotorvane machine mainly used for processing CTC black tea.

The Multi-Function Ride On Type Tea Harvester is a high-performance tool for commercial tea gardens. Featuring ride-on operation, adjustable picking parameters, and integrated collection/sorting, it replaces manual picking to save labor significantly. With 5-10x higher efficiency (0.3-0.8 ha/h) and precision plucking that preserves tea quality, it’s ideal for modern large-scale tea production.

DL-6CHL-CY30 belt type tea dryer use diesel heating, also can use gas heating, drying area 20m2, capacity 105kg per hour, click the photo to learn more details about our drying machine.

Pyramid/Triangle Tea Bag Filling Packaging Machine is widely applicable in tea processing plants, food and beverage companies, health product manufacturers, and OEM/ODM tea brands. It is suitable for packaging various teas, including loose-leaf tea, herbal tea, scented tea, functional tea, and instant tea, making it an essential equipment for upgrading the tea packaging process in both domestic and international markets.

Square Tray DL-6CH-6QB is a square tray baking cabinet-style Tea leaf baking machine, featuring stable temperature control, uniform heating, ideal for batch tea processing with efficient performance.

DL-6CFJ-20 used for black tea and dark tea processing, through the intelligent control of temperature and humidity, let tea oxidation fermentation to the best quality, machine has 5pcs stainless steel tray, capacity 60 kg per batch.

Witnessing Fresh Leaves Turning into Black Tea - The Charm of Handmade Black Tea.

The steps of making handmade black tea are not complicated, but each link is extremely important.

1️⃣ The first step: After fresh leaves are picked, they are withered first. Don't underestimate this step. Neither too long nor too short withering time is appropriate. If it is too short, the fresh leaves will be fragile when rolled. If it is too long, excessive moisture in the fresh leaves will evaporate. The fresh leaves are withered to the extent that the tea stems are bent and not easily broken and cannot be snapped even when twisted.

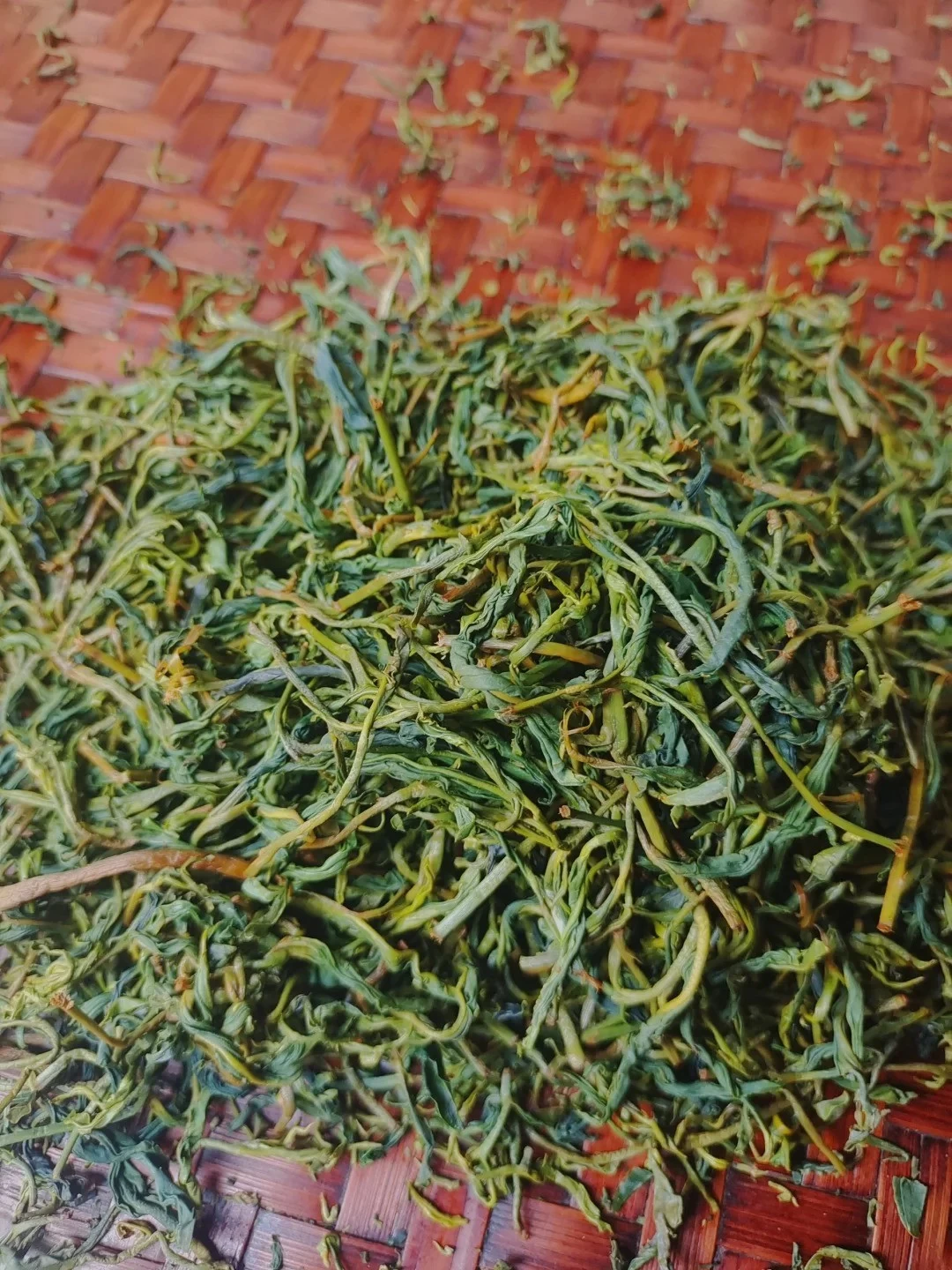

2️⃣ The second step: Rolling. This step is a great test of patience and is also a strenuous task. The rolling technique should be from light to heavy. If heavy force is used to roll at the beginning, some fresh leaves may be crushed (after all, withering cannot be so uniform). When rolling is almost done, increase the force. During the rolling process, the leaves will form a ball. Shake it in time to let the green flavor escape. Roll for a while, break up the ball. Roll for a while, break up the ball. This process should be continuous and it takes almost an hour to roll.

3️⃣ The third step: Fermentation. Put the rolled tea leaves in a warm place to ensure oxygen supply. The fermentation time is affected by factors such as temperature, humidity, oxygen supply, and thickness. Under normal conditions and suitable conditions, it generally takes 5 to 6 hours.

4️⃣ The fourth step: Stir-frying and drying. The pot temperature is 180℃ - 200℃. Put the fermented tea leaves into the pot and stir-fry. When the tea leaves become drier and drier, they can be dried in the pot. During the drying process, the turning action should be gentle to avoid breaking the tea leaves. After drying, the handmade black tea is completed.