The DL-6CYL-800 automatic tea cake pressing machine is applicable for pressing ball type tea, round tea cakes and square tea cakes. Its production capacity is 800-1000 pieces per hour. The sizes of tea cakes that this machine can produce are as follows: square tea cakes (25-40 mm), round tea cakes (25-45 mm), and ball type tea (27-35 mm).

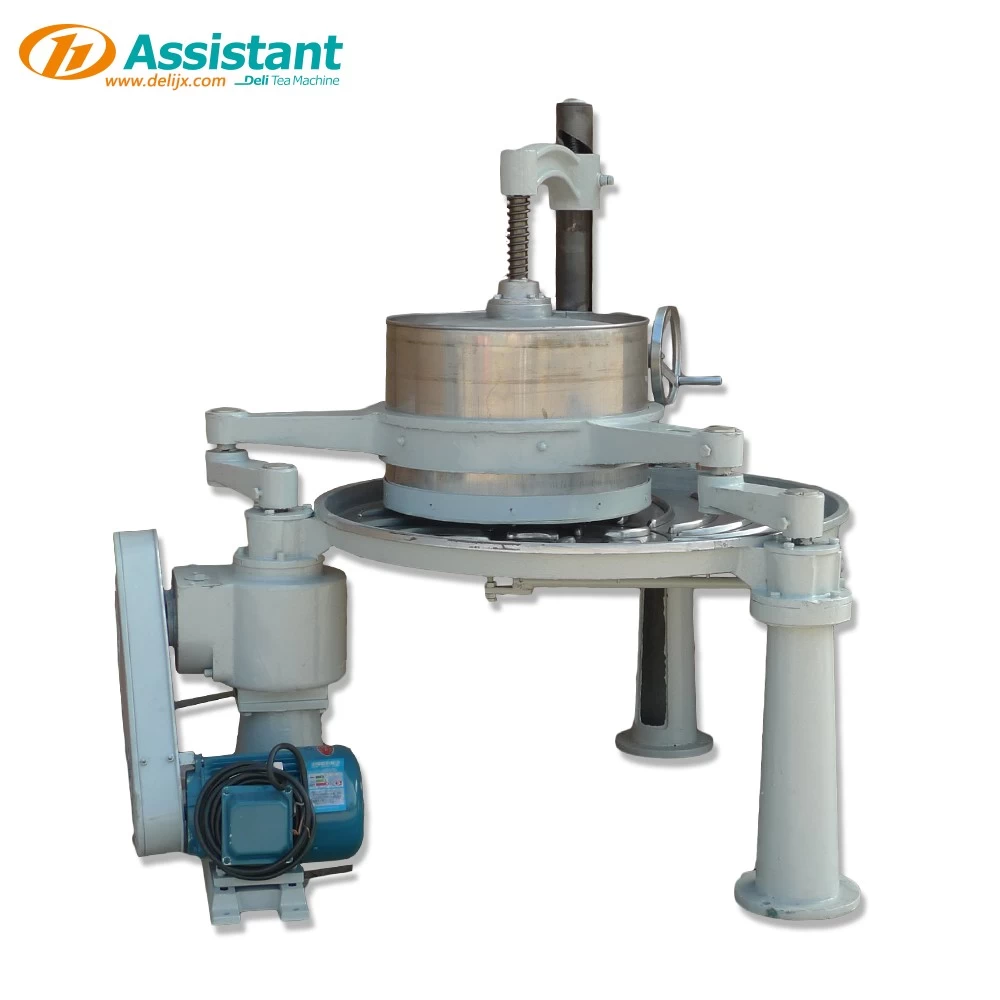

Oolong Tea Rolling Machine specializes in tea rolling and shaping. With precise pressure control, it releases tea juice, enhances aroma, ensures stable quality, and suits green tea, oolong tea, etc.—a top choice for tea enterprises.

DL-CRQ-20Z CTC black tea HRS Gyrovane rotorvane machine mainly used for processing CTC black tea.

The Multi-Function Ride On Type Tea Harvester is a high-performance tool for commercial tea gardens. Featuring ride-on operation, adjustable picking parameters, and integrated collection/sorting, it replaces manual picking to save labor significantly. With 5-10x higher efficiency (0.3-0.8 ha/h) and precision plucking that preserves tea quality, it’s ideal for modern large-scale tea production.

DL-6CHL-CY30 belt type tea dryer use diesel heating, also can use gas heating, drying area 20m2, capacity 105kg per hour, click the photo to learn more details about our drying machine.

Pyramid/Triangle Tea Bag Filling Packaging Machine is widely applicable in tea processing plants, food and beverage companies, health product manufacturers, and OEM/ODM tea brands. It is suitable for packaging various teas, including loose-leaf tea, herbal tea, scented tea, functional tea, and instant tea, making it an essential equipment for upgrading the tea packaging process in both domestic and international markets.

Square Tray DL-6CH-6QB is a square tray baking cabinet-style Tea leaf baking machine, featuring stable temperature control, uniform heating, ideal for batch tea processing with efficient performance.

DL-6CFJ-20 used for black tea and dark tea processing, through the intelligent control of temperature and humidity, let tea oxidation fermentation to the best quality, machine has 5pcs stainless steel tray, capacity 60 kg per batch.

Best for: Family farms, laboratories, and high-end small batch production.

If you are processing premium batches where delicate handling is required, small rolling machines are your best allies. These models are compact, energy-efficient, and often run on standard 220V power, making them accessible for smaller facilities.

Dimensions: Compact footprint (approx. 700-1000mm width).

Power: Low consumption (0.37 kW - 0.55 kW).

Capacity: Ideal for batches ranging from 3kg to 8kg.

Application: Perfect for experimental batches or high-value teas like artisanal Green Tea where leaf integrity is paramount.

Best for: Medium-sized tea factories and cooperative productions.

For businesses scaling up from manual processing to automation, the medium range offers the perfect balance between throughput and control. These machines typically require 380V industrial power and feature larger rolling discs for better leaf circulation.

DL-6CRT-40, DL-6CRT-45 & DL-6CRT-50:

Drum Diameter: 400mm - 500mm.

Power: 1.1 kW - 2.2 kW.

Capacity: Capable of handling approx. 15kg to 25kg per batch.

Feature: These models are heavy enough to provide sufficient pressure for Black Tea processing (which requires heavier cell breakage) while remaining gentle enough for Oolong.

Best for: Large-scale plantations and export-oriented mass production.

When daily output hits tons of fresh leaves, you need machines that can handle massive loads without compromising consistency. The large DL-6CRT series is built with robust gearboxes and heavy frames to withstand continuous operation.

DL-6CRT-65 to DL-6CRT-90:

Rolling Disc Diameter: Up to 1540mm for the massive DL-6CRT-90.

Power: 3 kW - 5.5 kW heavy-duty motors.

Capacity: Ranges from ≥60kg up to ≥300kg per batch.

Efficiency: The DL-6CRT-90 features a unique design where both the drum and disc move, maximizing rolling efficiency for large volumes.

Standard rolling machines (CRT series) are excellent for Strip-type teas (like most Black teas, Wuyi Rock tea, and some Green teas). However, if your product is Granular tea (like Iron Goddess/Tie Guan Yin or Gunpowder tea), you need specialized equipment.

Moon Type Tea Rolling Machine (DL-6CRT-30W): Designed specifically for granular shaping, utilizing a specialized disc and drum movement to curl leaves into tight pearls.

Selecting the right tea rolling machine depends on your "3 V's": Volume, Variety (Tea type), and Voltage availability.

Go Small (DL-6CRT-25/30) for artisan quality and 220V convenience.

Go Medium (DL-6CRT-45/50) for the sweet spot of commercial production.

Go Large (DL-6CRT-65+) for maximum industrial efficiency.

Ready to upgrade your tea line? Contact us to get the full specification sheet for the 2024 models.